Creating In-Office Dental Restorations With Computers

Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) Makes The Virtual Real In Dentistry

As we journey into the 21st century, technology is touching our lives in ways we could hardly have envisioned a couple of decades ago. Computers can make our travel arrangements, take us to a virtual college classroom — even reveal a 3D virtual world from a movie director's imagination. But today the virtual world is actually morphing into the real one, right in the dentist's office. Computers are being used to fabricate new crowns, veneers and fillings for teeth — before your very eyes. It's true, and actually has been for years.

Dental technology known as Computer-Aided Design/Computer-Aided Manufacturing, or CAD/CAM, recently turned 25. During its first quarter-century, innovations to the system have made CAD/CAM feasible for most dental practices. Dentists who choose to use this technology — and their ranks are growing — can now create laboratory-grade dental restorations in minutes. To understand how truly extraordinary this is, let us first look at the traditional way of designing and manufacturing a dental crown (cap).

Once Upon A Time

In the traditional repair of a badly decayed tooth, a dentist removes the decay and prepares (drills) the tooth so that it can be restored to its original shape, function and looks, the first step in a process commonly known as crowning or capping. The next step is to take an impression of the prepared tooth (a very detailed and accurate physical replica of the prepared surfaces) together with the adjacent teeth by using a rather goopy, putty-like impression material. The material is left to set for five minutes, after which time it is removed. Liquid stone is then poured into the impression, which, once cured, provides an indelibly accurate model of the teeth and bite. A laboratory technician uses this model to make the crown, building up layers of dental porcelain (in powdered form) until the correct shape is achieved. The crown is then fired in an oven, turning powdered glass into porcelain, which is stained and/or glazed for a realistic finish. It's a labor-intensive process that requires a skilled, artistic eye and hand. Communication between dentist and technician is also crucial to make sure the result will fit, both physically and aesthetically, with the individual's existing natural teeth.

The process, which can take weeks, ends with the finished crown arriving at the dentist's office. The patient will have a second appointment during which the crown is either cemented or bonded to the tooth, and adjusted to fit exactly to the prepared tooth and with the existing bite. It's a tried and true method with both its advantages and disadvantages, but now — enter CAD/CAM.

|

|

| A dentist holds a scanning wand (connected to a digital camera), which uses blue wavelength light to record images of the teeth to make a 3D computer model. |

|

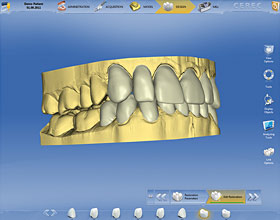

| A 3D model created by the scanning wand is displayed on a computer screen. |

|

| Blocks of dental ceramic material that will be used to create dental restorations. |

|

| A milling machine located inside the dental office carves a restoration from a block of ceramic material. |

|

| Upper and lower gold restorations that need to be replaced. |

|

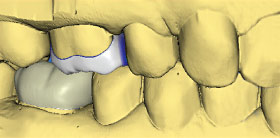

| A computer model showing how the final restorations will look is sent to the milling machine for fabrication. |

|

| The final restorations, placed the same day. |

Fairy Dust And Magic Wands

The CAD/CAM process starts the same way, removing the decay from the tooth and preparing it to retain a crown. But instead of making a physical mold of your teeth, a virtual model is created on a computer. What goes in your mouth is not a mouthful of impression material, but rather a light dusting of reflective powder that allows the dentist to capture multiple images of your teeth with, believe it or not, a small scanning wand.

The latest digital cameras will record the images automatically, using light of blue wavelength, which gives enough depth to record all the hills and valleys of the prepared tooth surfaces. It's as if you were scanning the surface of the moon and sending every detail back to earth.

In seconds, the dentist will have a highly accurate 3D digital model of your teeth that is used first to assess whether your tooth has been adequately prepared for restoration. If needed the dentist can make corrections to the tooth, and then easily take another series of images.

Once the images of the prepared tooth are satisfactory, the light coating of reflective dust is easily rinsed from your mouth. The dentist will then design a crown, or veneer or filling, with the help of design software that contains a database of thousands upon thousands of tooth forms from which to draw and match your natural teeth. It's like trying on a million coats or dresses, until the perfect fit, style, and shape are found. The software has some other amazing features too, including a replication function that can create a mirror-image twin of the same tooth on the other side of your mouth. For example, if your dentist is capping your right front tooth, he or she can use the scanned information from the left front tooth to create crown contours that provide a mirror image.

The next step is for the dentist to choose a small block of matching dental ceramic material from which to mill the crown. CAD/CAM materials have been improved over the years, offering greater strength and a more lifelike appearance. Crowns made from these new materials often don't need additional coats of stain or glazing to create a good match. Once your dentist chooses the material, you are now only minutes, not weeks, away from a fully restored tooth.

The computer's digital design is transmitted to a milling machine that can carve the crown from the block of ceramic in about five minutes. After the milling is completed, the dentist will take the crown from the milling unit and check the fit and make any necessary adjustments right then and there. The dentist can refine the milled ceramic surface in several ways, such as using various finishing tools to create a “wet-look” surface gloss. Stains and glazes can be applied and fired in 12 minutes or less. Once finishing is complete, the crown is physically bonded to the tooth preparation, restoring it to normal shape, function and aesthetics, and even strengthening it in the process.

The fit and finish of restorations created with CAD/CAM are as accurate as those produced in a dental laboratory with the same materials, but all of this has taken place within one office visit, without the involvement of a dental laboratory or the need for individuals to communicate effectively. The Tooth Fairy could hardly have done better!

This is not to say that machines can now do it all and individual expertise no longer matters. On the contrary, your dentist's training and artistic eye are more important than ever. And there is certainly a learning curve with every technology — you may remember your own efforts learning to use your first computer. In the right and experienced hands, however, CAD/CAM technology offers tremendous benefits to both patient and doctor.

Happily Ever After

Studies have shown that CAD/CAM restorations are demonstrating success rates similar to restorations fabricated using time-tested materials and techniques.

Continual evolution of the CAD/CAM system over the past 25 years has increased the speed and precision with which dentists can place high-quality, aesthetic restorations in many situations that in the past required traditional approaches. As a direct result of CAD/CAM technology, dental ceramics used today are higher in quality than those used in the past. And improvements to CAD/CAM hardware, software and materials continue to blur any remaining distinctions between the dental office and laboratory.

Since 1985, when the system first appeared in dental offices, more than 27,000 CAD/CAM units have been installed for in-office use in more than 50 countries. Dentists have placed more than 20 million restorations produced with these units and the technology is part of many dental schools' curricula. As present trends will in all likelihood continue, this extraordinary state-of-the-art technology may soon be coming to a dental office near you.